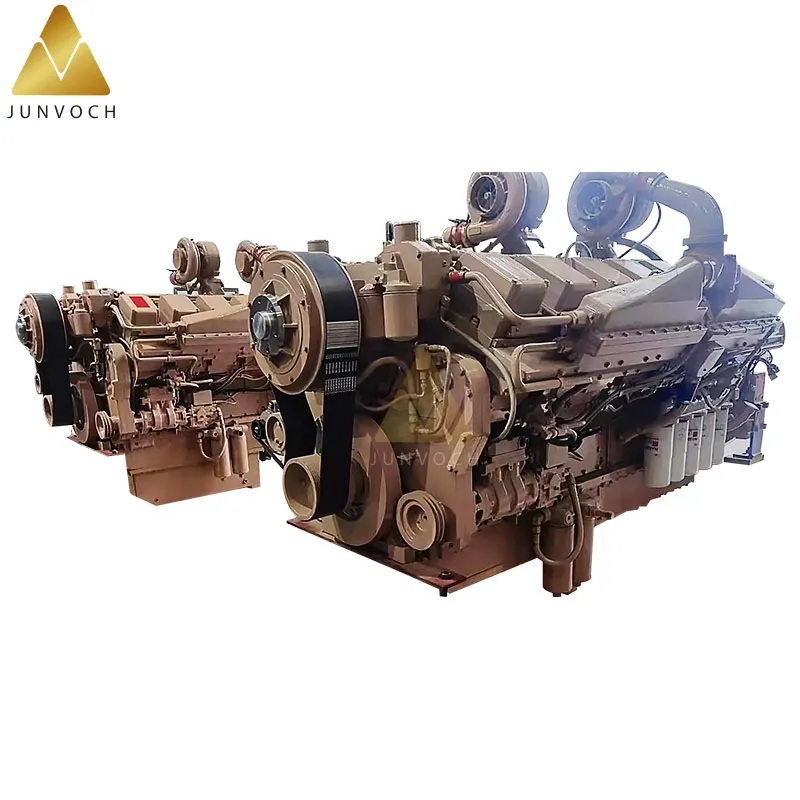

When it comes to reliable heavy-duty engines, the Cummins K50 has earned a solid reputation in various industrial and marine applications. As a critical part of the Cummins engine lineup, the K50 offers durability, power, and efficiency. For those involved in maintenance or repair, understanding the key components and available engine parts is essential.

What Is the Cummins K50 Engine?

First and foremost, the Cummins K50 is a naturally aspirated, 5.0-liter inline six-cylinder diesel engine. It has been widely used in heavy trucks, buses, and marine vessels, thanks to its robust design and proven performance. Unlike turbocharged engines, the K50 relies on atmospheric pressure, which simplifies maintenance and enhances reliability.

Key Features That Make the K50 Stand Out

To begin with, the K50 engine features a cast iron block and head, which contributes to its longevity and resistance to wear. Additionally, it has a mechanical fuel injection system, ensuring consistent fuel delivery under various operating conditions.

Moreover, the K50 operates efficiently at a moderate RPM range, making it ideal for applications requiring steady power output rather than high-speed performance. This characteristic often translates to lower fuel consumption and longer engine life.

Essential Cummins K50 Engine Parts to Consider

When servicing the K50 engine, several components frequently require replacement or inspection:

- Fuel Injection Pump: Since the K50 uses a mechanical fuel system, the injection pump is critical for proper engine function. Regular maintenance can prevent fuel delivery issues.

- Cylinder Head Gasket: A common wear item, the head gasket maintains the seal between the cylinder head and engine block. Replacing it promptly can avoid costly engine damage.

- Pistons and Rings: Over time, piston wear affects engine compression and performance. Quality replacement parts ensure the engine runs smoothly.

- Water Pump: Cooling system components like the water pump are vital for preventing overheating, especially in heavy-duty use.

By using genuine or high-quality aftermarket Cummins parts, you can keep your K50 engine operating at peak performance.

Why Choose Genuine Cummins Engine Parts?

Furthermore, opting for authentic Cummins parts guarantees compatibility and durability. These parts are engineered to meet rigorous standards, ensuring your engine maintains reliability and efficiency. In contrast, inferior or generic parts may lead to premature failures or decreased engine performance.

Conclusion: Maintaining Your Cummins K50 Engine for Longevity

In conclusion, the Cummins K50 remains a trusted engine for many applications due to its straightforward design and durability. However, like all diesel engines, proper maintenance and timely replacement of key parts are crucial. Whether you need fuel injection components, gaskets, or cooling system parts, choosing reliable Cummins engine parts is the best way to extend your engine’s life and optimize performance.