Gaskets play a crucial role in the performance and reliability of Cummins engines. Acting as seals between engine components, they prevent leaks of fluids and gases while maintaining optimal pressure. Choosing the right gasket and ensuring timely replacement can prevent engine damage and extend service life.

Common Types of Cummins Engine Gaskets

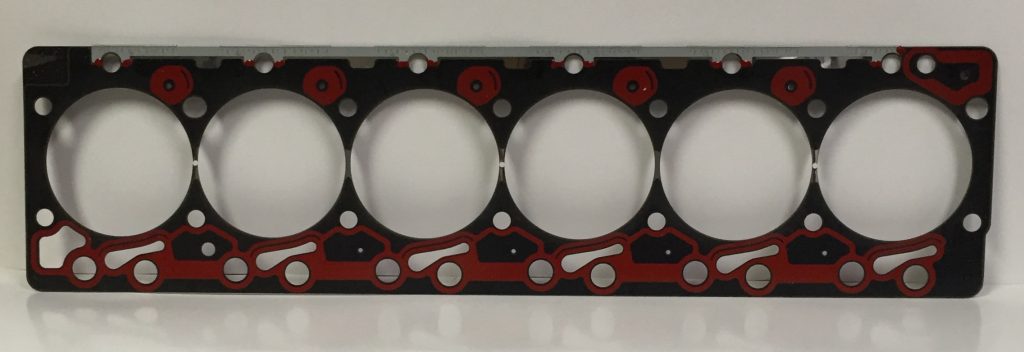

1. Head Gaskets

Head gaskets seal the cylinder head to the engine block, ensuring combustion gases remain contained while preventing coolant or oil leaks. A damaged head gasket can lead to engine overheating, reduced performance, and even severe engine failure.

2. Oil Pan Gaskets

These gaskets seal the oil pan to the engine block, preventing oil leaks. Regular inspection is vital, especially after long periods of engine operation, as oil leaks can damage engine components.

3. Valve Cover Gaskets

Located on top of the engine, valve cover gaskets prevent oil from leaking out of the valve cover area. They also protect the engine from dirt and debris.

4. Intake and Exhaust Manifold Gaskets

These gaskets ensure a tight seal between the engine block and the intake or exhaust manifolds, preventing air, fuel, or exhaust leaks that can affect engine efficiency and emissions.

5. Water Pump Gaskets

Water pump gaskets maintain a secure seal around the pump, preventing coolant leaks that could lead to engine overheating.

Signs That a Cummins Gasket Needs Replacement

- Overheating Engine: Often caused by a blown head gasket or failing water pump gasket.

- Fluid Leaks: Oil, coolant, or fuel leaks around the engine indicate worn or damaged gaskets.

- Reduced Engine Performance: Loss of compression or misfires can be related to gasket failure.

- Unusual Noises: Hissing or tapping sounds from the engine may signal escaping gases or fluids.

Tips for Replacing Cummins Engine Gaskets

- Use Genuine Parts: Always choose OEM Cummins gaskets to ensure proper fit and durability.

- Follow Torque Specifications: Incorrect torque can cause leaks or premature gasket failure.

- Clean Surfaces Thoroughly: Ensure mating surfaces are free of debris, old gasket material, and oil.

- Inspect Adjacent Components: While replacing gaskets, check seals, bolts, and surrounding parts for wear.

Regular Maintenance: Routine inspections can catch gasket wear early, avoiding costly repairs.

By understanding the types of gaskets, their functions, and proper replacement techniques, Cummins engine owners can maintain optimal performance and prevent potential engine damage. Regular maintenance and timely gasket replacement are key to keeping engines running smoothly for years.