Modern diesel engines are no longer just mechanical powerhouses; they are precision machines heavily governed by electronics. At the heart of this transformation is the ECM, or Engine Control Module. In Cummins engines, the ECM plays a central role in performance optimization, emissions control, fuel efficiency, and fault diagnostics.

What Is an ECM?

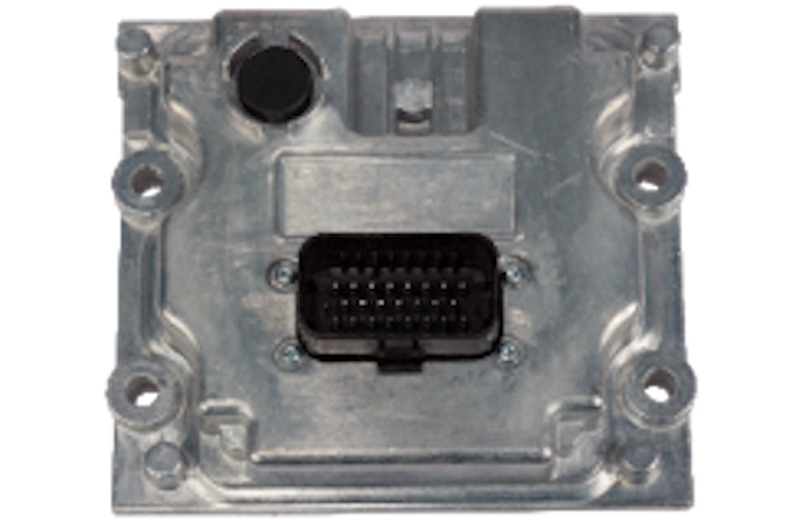

The ECM is essentially the brain of the engine. It is an advanced onboard computer that continuously collects data from various sensors located throughout the engine. Based on this real-time data, it makes rapid decisions to adjust engine parameters such as fuel injection timing, air-to-fuel ratio, turbo boost pressure, idle speed, and more. These constant adjustments ensure optimal engine performance under varying loads and environmental conditions.

Core Functions of a Cummins ECM

Fuel Management:

The ECM calculates the ideal amount of fuel to be injected at any given moment, maximizing combustion efficiency while reducing fuel consumption and emissions.

Air Intake and Turbocharger Control:

By monitoring the air intake temperature, pressure, and volume, the ECM controls the operation of the turbocharger, ensuring optimal air-fuel mixing and power output.

Emissions Regulation:

Cummins engines are designed to comply with strict environmental regulations. The ECM manages systems like the Exhaust Gas Recirculation (EGR), Diesel Particulate Filter (DPF), and Selective Catalytic Reduction (SCR) to maintain compliance without compromising performance.

Engine Protection:

To prevent engine damage, the ECM constantly checks vital parameters such as coolant temperature, oil pressure, and RPM. If something exceeds safe limits, it can initiate protective actions like derating power or shutting down the engine.

Diagnostics and Fault Detection:

A significant advantage of the ECM is its ability to detect and log faults. Using onboard diagnostics (OBD), the ECM can store error codes that help technicians quickly identify and resolve issues, reducing downtime.

Benefits of ECM in Cummins Engines

Improved Fuel Efficiency:

With precise fuel and air control, Cummins ECMs help reduce unnecessary fuel burn, especially during idle or low-load operations.

Consistent Performance:

Whether driving uphill, towing a heavy load, or idling at a stoplight, the ECM ensures smooth engine response and consistent power delivery.

Reduced Maintenance Costs:

By proactively monitoring engine health and identifying problems early, ECMs help reduce unexpected breakdowns and expensive repairs.

Regulatory Compliance:

Meeting EPA and global emission standards is essential. The ECM ensures the engine runs cleanly while still maintaining power and reliability.

Troubleshooting ECM Issues

Like any electronic component, ECMs can sometimes fail or develop communication issues. Common signs include erratic engine behavior, poor fuel economy, starting problems, or warning lights on the dashboard. When diagnosing such problems, using a Cummins-compatible diagnostic tool is essential to retrieve fault codes and determine the root cause.

In some cases, ECMs can be reprogrammed or reflashed to update software or correct performance issues. However, if the ECM hardware is damaged, replacement may be necessary.

Final Thoughts

The ECM is indispensable in modern Cummins engines. It governs nearly every aspect of engine operation and plays a crucial role in achieving performance, reliability, fuel efficiency, and compliance with emissions standards. Whether you operate heavy-duty trucks, construction machinery, or power generators, understanding the ECM’s role can help ensure your engine runs at its best for years to come.