When it comes to heavy-duty diesel engines, Cummins has long been a name synonymous with power, reliability, and innovation. Among its many celebrated engine models, the Cummins KTA19 and QSK19 stand out as two of the most widely used engines across industrial, marine, and power generation sectors.

But what truly sets these two engines apart—especially in the area of turbocharging technology? In this article, we take a closer look at how Cummins evolved its turbocharging systems from the legendary KTA19 to the more modern and efficient QSK19, and what that means for performance, emissions, and long-term maintenance.

The KTA19: Classic Design with Proven Performance

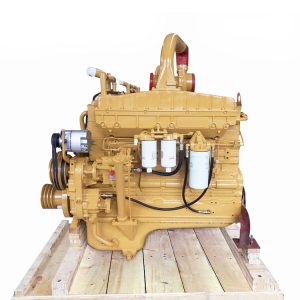

The Cummins KTA19 Parts is a workhorse that has powered equipment for decades. With a displacement of 19 liters and a robust inline 6-cylinder configuration, the KTA19 is known for:

- Mechanical fuel system

- Single-stage turbocharging

- High torque output

- Simplicity in design and maintenance

Turbocharging in the KTA19 is straightforward: a single turbocharger boosts air intake, increasing engine power and efficiency. While effective, the system lacks the precision of modern turbo setups.

For customers seeking reliable power in remote areas or applications where emissions standards are less stringent, the KTA19 remains a preferred choice.

The QSK19: A Modern Powerhouse with Advanced Turbocharging

Enter the Cummins QSK19, the next-generation engine that takes everything good about the KTA19 and builds on it with cutting-edge technology:

Electronic fuel injection system

Advanced turbocharging with intercooling

Integrated ECM for engine diagnostics and fuel optimization

Lower emissions compliance (Tier 2, Tier 3, Tier 4)

The QSK19 uses high-performance turbocharging systems that enable precise air-fuel management, resulting in:

- Higher fuel efficiency

- Reduced exhaust emissions

- Improved responsiveness and durability

Many models of the QSK19 also employ dual-stage turbocharging, combining low and high-pressure turbos to enhance performance across all RPM ranges. This represents a significant leap from the KTA19’s single turbo configuration.

KTA19 vs QSK19: Key Turbocharging Differences

| Feature | KTA19 | QSK19 |

|---|---|---|

| Turbocharger | Single-stage | Dual-stage (optional) |

| Fuel System | Mechanical | Electronic |

| Emissions | Higher | Lower (EPA-compliant) |

| Efficiency | Moderate | High |

| Maintenance | Simpler | Requires advanced diagnostics |

If you’re upgrading or servicing engines, understanding these differences is crucial. The QSK19 may require more complex support, but it delivers superior performance and meets stricter environmental standards.

Why It Matters for Cummins Engine Parts Buyers

Whether you’re sourcing Cummins KTA19 parts or QSK19 components, knowing how the turbo systems differ can guide your purchase decisions. For instance:

Turbochargers on QSK19 engines are more sensitive to fuel and air quality.

Intercoolers and sensors on QSK19 are critical components that require periodic inspection.

KTA19 parts may be more abundant and easier to maintain in remote regions.

As a professional Cummins parts supplier, we stock a complete range of genuine and aftermarket KTA19 and QSK19 engine parts, including turbochargers, gaskets, intercoolers, and fuel system components.

Conclusion: Evolution That Delivers

The evolution from the KTA19 to the QSK19 reflects Cummins’ dedication to performance, durability, and environmental responsibility. Understanding their differences—especially in turbocharging—empowers equipment owners and maintenance teams to make better decisions.