Mining operations demand exceptional durability from every machine component. Dust, heavy loads, and continuous operation place extreme stress on engines. For operators running Cummins-powered mining equipment, the right components make the difference between maximum uptime and costly breakdowns.

The following Cummins engine parts are proven to deliver strength, efficiency, and long service life, even in the harshest mining conditions.

1. Heavy-Duty Fuel Injectors

Fuel injectors are the heart of the combustion process. In mining machinery, they must withstand high pressures, intense vibration, and fuel impurities.

- Why it matters: Precision fuel delivery improves efficiency and reduces harmful emissions.

- Best choice: Genuine Cummins injectors such as 4921431 or 3411756 are engineered to resist wear and maintain performance in abrasive environments.

Transition: While fuel injectors keep combustion efficient, airflow must also be optimized—this is where turbochargers excel.

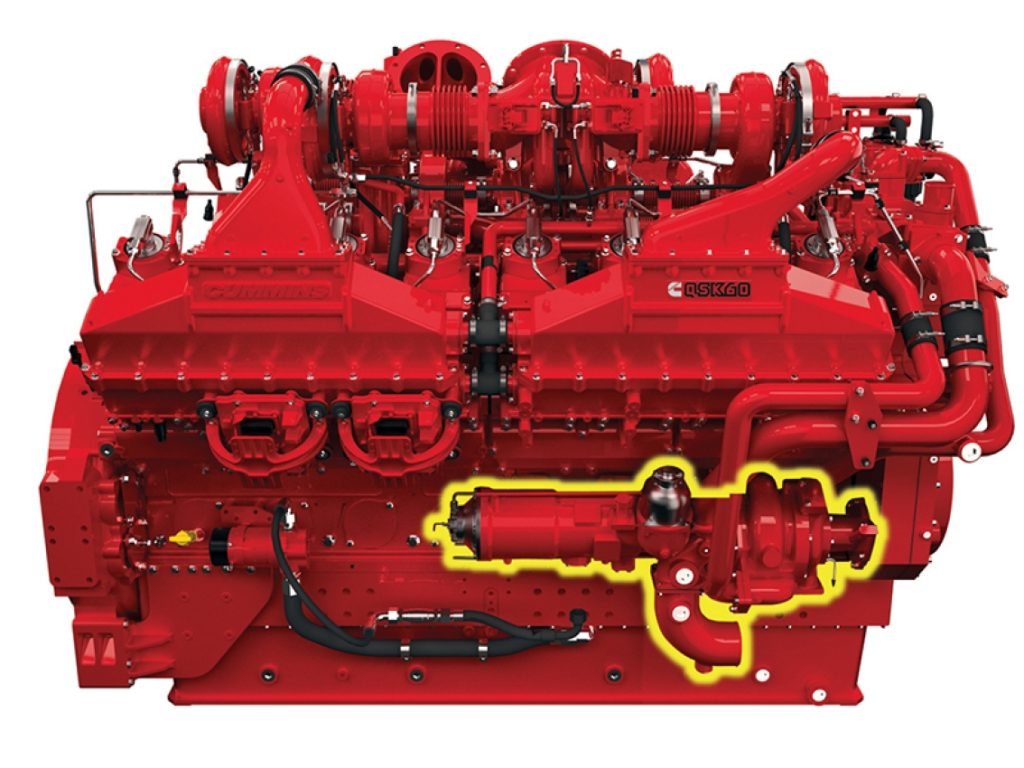

2. Turbochargers for Maximum Power

Large mining trucks and loaders require immense torque and horsepower. A well-matched Cummins turbocharger ensures optimal air supply for complete combustion.

- Why it matters: Increased power without sacrificing fuel efficiency is critical for heavy loads and steep gradients.

- Best choice: The Holset HX55 and HX60 turbochargers, often used in Cummins QSK series engines, deliver reliable boost under extreme workloads.

Transition: High power must be supported by equally strong internal engine components, starting with main and rod bearings.

3. High-Strength Main and Rod Bearings

Bearings carry the load of the crankshaft and connecting rods. In mining applications, they face extreme pressures and constant motion.

- Why it matters: Durable bearings extend crankshaft life and prevent sudden engine failure.

- Best choice: Cummins OEM main bearing sets like 3802070 are built for sustained heavy-duty operation.

Transition: Once the moving parts are protected, heat management becomes the next priority.

4. Heavy-Duty Water Pumps

Mining sites often operate in high-temperature conditions. A reliable Cummins water pump maintains steady coolant circulation to prevent overheating.

- Why it matters: Proper engine temperature control reduces wear and avoids unplanned downtime.

- Best choice: Genuine Cummins water pumps such as 3803285 are designed to perform in hot, dusty environments.

Transition: In addition to cooling, preventing contaminants from entering the system is vital.

5. High-Efficiency Filtration Systems

Mining generates large amounts of airborne dust and debris that can quickly damage engines. High-quality filtration keeps air, fuel, and oil clean.

- Why it matters: Cleaner systems last longer and maintain peak performance.

- Best choice: Fleetguard filters, manufactured to Cummins specifications, provide superior protection for mining engines.

Final Thoughts

Mining equipment operates under relentless pressure. Using genuine Cummins engine parts—from injectors and turbochargers to bearings, water pumps, and filters—ensures reliable performance, extended service life, and reduced downtime. In the mining industry, dependable components are not a luxury; they are the foundation of productivity.